Overview of ABW-153 Smooth Oil-Covered 3 Production Process

The ABW-153 Smooth Oil-covered 3 Production process represents a significant advancement in industrial coating technology, combining efficiency with high-quality results. This process involves applying a specialized oil-based coating to products, ensuring smoothness, durability, and enhanced performance. As industries demand more reliable and aesthetically appealing coatings, understanding the intricacies of ABW-153 production becomes essential. This article provides a comprehensive overview of the process, highlighting its key features, operational procedures, quality control measures, challenges, and potential future improvements.

Overview of ABW-153 Smooth Oil-covered 3 Production Process

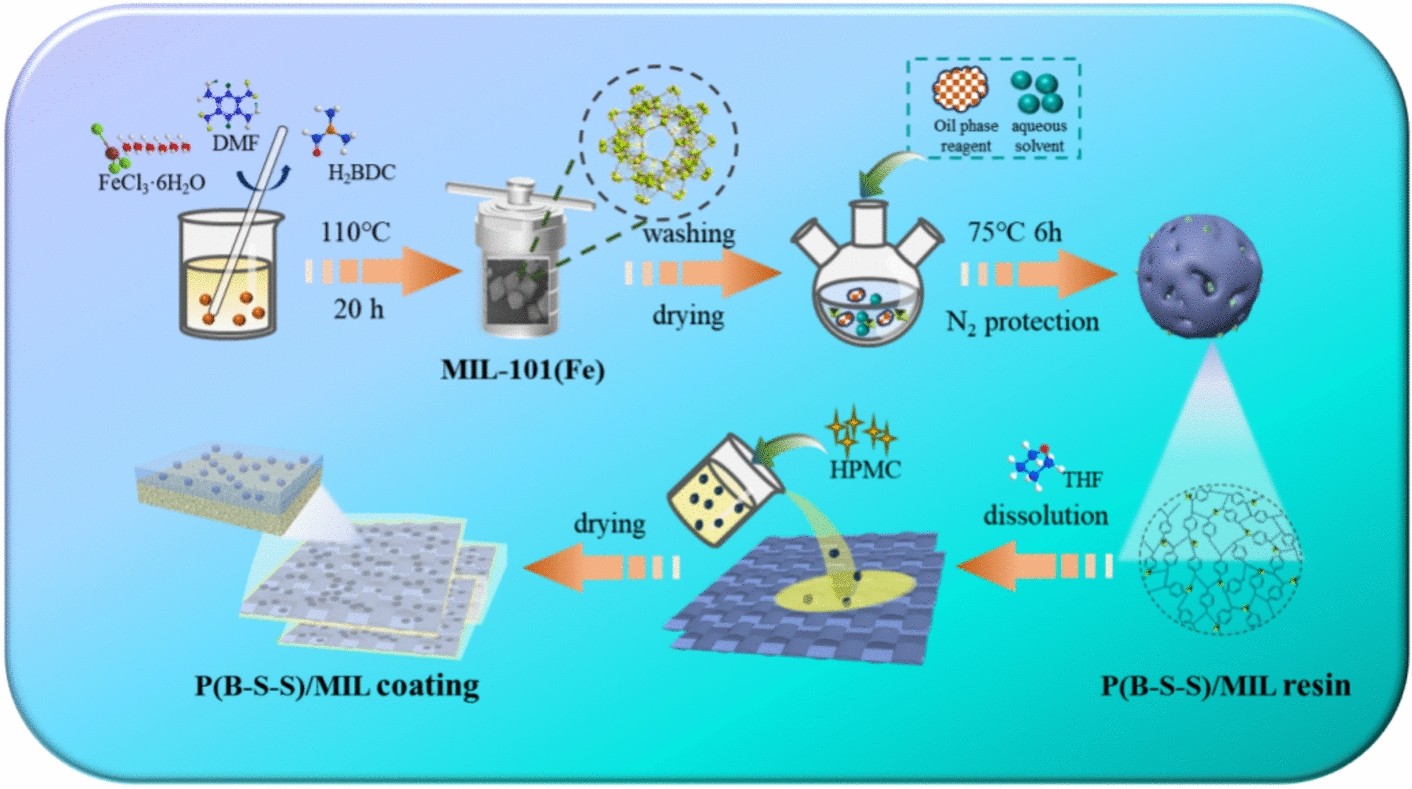

The ABW-153 production process is designed to produce a uniform, oil-covered surface on various industrial components, primarily focusing on achieving a smooth and durable finish. It begins with preparing the raw materials, which are thoroughly cleaned to remove contaminants that could impair coating adhesion. The core of the process involves applying a specially formulated oil-based coating that adheres uniformly across the product surface. The process is carefully controlled to ensure consistency in thickness and coverage, which is critical for performance and aesthetic appeal. Once coated, products typically undergo a curing phase, where heat or air exposure solidifies the oil layer, forming a protective barrier. The entire process emphasizes efficiency, repeatability, and adherence to safety standards, making it suitable for large-scale production lines.

The production process is often integrated into automated manufacturing systems to maximize throughput and minimize human error. Modern ABW-153 lines utilize advanced spraying or dipping techniques, combined with real-time monitoring sensors that adjust parameters such as flow rate, temperature, and coating thickness. This integration allows for precise control over the coating quality and reduces waste. Additionally, the process incorporates environmental considerations, such as controlling VOC emissions and recycling excess coating materials. Overall, the ABW-153 process is a sophisticated blend of chemistry, engineering, and automation, designed to deliver high-quality, oil-covered products efficiently.

The process flow typically involves several stages: initial cleaning, coating application, curing, and inspection. Each stage is critical to ensuring the final product meets strict quality standards. The process is adaptable to different product geometries and sizes, making it versatile across various industries, including automotive, electronics, and industrial machinery. The use of oil-based coatings offers advantages such as excellent corrosion resistance, ease of application, and a smooth finish that enhances the product’s appearance and durability. As industries evolve, the ABW-153 process continues to be refined, incorporating new materials and technologies to meet emerging demands for performance and sustainability.

In summary, the ABW-153 Smooth Oil-covered 3 Production process is a carefully orchestrated sequence of steps aimed at producing high-quality, oil-coated products with precision and efficiency. Its integration of automation, environmental controls, and adaptable techniques positions it as a leading solution in modern manufacturing. Continuous improvements and innovations in this process promise to further enhance product quality, reduce costs, and minimize environmental impact.

Key Features and Characteristics of ABW-153 Oil Coverage

The ABW-153 oil coverage is distinguished by its exceptional smoothness and uniformity, which are critical for both functional and aesthetic purposes. The coating forms a seamless layer that adheres tightly to the substrate, providing a consistent surface that resists peeling, cracking, or uneven wear. Its formulation is designed to offer excellent lubricity, corrosion resistance, and environmental stability, making it suitable for products exposed to harsh conditions. The oil used in ABW-153 is typically a high-quality, refined compound that ensures minimal odor, low volatility, and long-lasting performance.

One of the key characteristics of ABW-153 oil coverage is its ability to produce a glossy, smooth finish that enhances the visual appeal of the final product. This is achieved through precise control of the application process, which ensures an even distribution of oil without drips or bubbles. The oil layer also provides a degree of flexibility, allowing the coating to accommodate slight deformations or thermal expansions without cracking. Additionally, the coating’s hydrophobic nature helps repel water and contaminants, further extending the lifespan of the coated product.

The chemical properties of ABW-153 oil contribute to its durability and resistance to environmental factors. It exhibits excellent resistance to oxidation, UV degradation, and chemical exposure, which are common challenges in industrial settings. The oil’s low surface tension facilitates smooth application and ensures complete coverage, even on complex geometries. Its compatibility with various substrates, including metals and plastics, makes it a versatile choice across different manufacturing sectors. Moreover, the oil’s formulation is optimized to minimize environmental impact, with low VOC emissions and biodegradable components where possible.

In terms of maintenance, products coated with ABW-153 oil are easier to clean and maintain due to the lubricating and hydrophobic properties of the coating. This characteristic reduces the accumulation of dirt, grease, and other contaminants, simplifying cleaning procedures and reducing downtime. The oil coverage also enhances the overall resistance of the product to corrosion and wear, thereby improving its functional lifespan. These features collectively make ABW-153 oil coverage not only a protective layer but also a value-added enhancement for various industrial applications.

Overall, the key features of ABW-153 oil coverage—its smoothness, durability, environmental stability, and ease of application—make it a preferred choice in modern manufacturing. Its ability to combine aesthetic appeal with functional performance underscores its importance in industries where product longevity and appearance are critical. As technological advancements continue, the characteristics of ABW-153 oil coverage are expected to evolve, further expanding its applicability and effectiveness.

Step-by-Step Procedures in ABW-153 Production Workflow

The ABW-153 production workflow is a meticulously structured process that ensures consistent quality and efficiency. The first step involves thorough cleaning of the raw materials to eliminate oils, dirt, and other contaminants that could hinder coating adhesion. This cleaning process often employs ultrasonic cleaning, solvent washes, or plasma treatments, depending on the substrate material. Once cleaned, the products are dried in controlled environments to prevent any residual moisture from affecting the coating process.

Following preparation, the next step is the application of the ABW-153 oil coating. This can be achieved through various techniques such as spraying, dipping, or brushing, with automated systems preferred for large-scale production. During application, parameters like spray pressure, nozzle size, and dipping duration are precisely controlled to ensure uniform coverage. The coating is typically applied in multiple thin layers rather than a single thick layer to promote better adhesion and surface finish. After each application, the products may undergo a brief drying phase to allow the coating to set before subsequent layers are added.

The curing phase is crucial for achieving the desired properties of the oil coating. Depending on the formulation, curing can involve thermal processes in ovens or ambient air curing with controlled humidity. This step solidifies the oil layer, ensuring it forms a durable, adherent, and smooth surface. Post-curing, the products are subjected to inspection to verify coating thickness, uniformity, and adhesion quality. Non-destructive testing methods such as ultrasonic thickness gauges, visual inspections, and adhesion pull tests are commonly employed to ensure standards are met.

Final quality assurance includes additional steps like surface polishing or buffing if necessary, to enhance the smoothness and aesthetic appeal. The coated products then undergo packaging and storage procedures that protect the oil layer from contamination or damage during transportation. Throughout the workflow, process parameters are continuously monitored and adjusted through automated control systems to maintain consistency. Proper documentation and record-keeping are also vital for traceability, quality audits, and process improvements.

In essence, the step-by-step procedures in ABW-153 production are designed to optimize coating quality while maintaining efficiency. The integration of automation, precise control, and rigorous inspection ensures that each product meets the specified standards. This systematic approach allows manufacturers to produce high-quality, oil-covered components reliably on a large scale, supporting various industrial applications with confidence.

Quality Control Measures for ABW-153 Oil Coating

Quality control in the ABW-153 production process is fundamental to ensuring the final products meet stringent standards for performance and appearance. The initial phase involves verifying raw material quality, ensuring that the oil formulation and substrates conform to specified chemical and physical properties. During application, real-time monitoring systems track parameters such as coating thickness, flow rate, and temperature, enabling immediate adjustments to prevent defects. Automated sensors and feedback loops are employed to maintain consistent coating quality across all products.

Post-application, rigorous inspection protocols are implemented. Visual inspections are conducted to identify surface imperfections such as drips, bubbles, or uneven coverage. Non-destructive testing methods, including ultrasonic thickness measurements and adhesion tests, are used to assess the coating’s uniformity and adherence. Thickness gauges ensure the oil layer meets the predetermined specifications, preventing issues related to under- or over-coating. These inspections are often complemented by photographic documentation and statistical process control (SPC) techniques to monitor process stability over time.

Environmental conditions within the production environment are also tightly controlled as part of quality assurance. Temperature, humidity, and air quality are maintained within specified ranges to prevent defects such as cracking, peeling, or contamination. Regular calibration of equipment and adherence to safety standards further contribute to consistent product quality. Additionally, sampling of finished products for comprehensive testing, including corrosion resistance, flexibility, and chemical stability, ensures that the coating performs reliably under operational conditions.

To address potential defects, corrective actions are systematically implemented. For example, if coating thickness deviates from the standard, adjustments are made to application parameters or the defective batch is reprocessed or rejected. Feedback from quality assessments informs continuous process improvements, fostering a culture of quality excellence. Documentation of all inspection results and corrective actions provides traceability and supports compliance with industry standards and certifications.

Overall, the quality control measures for ABW-153 oil coating encompass a combination of real-time monitoring, rigorous inspections, environmental controls, and systematic corrective procedures. These measures ensure that each product not only meets design specifications but also performs reliably in its intended application. Effective quality control is essential for maintaining customer satisfaction, reducing waste, and enhancing the overall reputation of the manufacturing process.

Challenges and Solutions in the ABW-153 Production Line

The ABW-153 production line faces several challenges, primarily related to maintaining